Bài tập case study môn AIB

BEDFORSHIRE UNIVERSITY

FOREIGN TRADE UNIVERSITY

Faculty of International Education

************

Cyclermate Case study

Subject: Applied Integrated Business

Instructor: Cao Dinh Kien

Student: Nguyễn Kim Oanh

HANOI, NOVEMBER 2015

Table of Contents

Executive summary.............................................................................................................................3

I.

Introduction.................................................................................................................................6

II.

SWOT analysis.........................................................................................................................6

III.

Company issues and solution................................................................................................11

1.

Production and operation......................................................................................................11

2.

Human relation......................................................................................................................12

3.

Marketing...............................................................................................................................14

4.

Financial projections.............................................................................................................14

IV.

Recommendation...................................................................................................................17

1.

Short- term.............................................................................................................................17

2.

Long-term...............................................................................................................................17

V.

VI.

Conclusion..................................................................................................................................17

References..............................................................................................................................18

Executive summary

Historical background

In 1988, Lewis Llewwllyn and Dai Amstrong were unemployment from the

closure of their town’s steel works in south Wales. They decided to use their

savings to set up a bicycle manufacturing business, given shared interest, and

combined expertise.

They selected a “ traditional” upright cycle segment with retro style. They

believed that their factory would be development in ‘niche’ market.

The beginning was smoothly, they had two order in the first week and the

relationship with some bicycle store was set up.

By the end of 1990, the business had grown to such an extent that they were

unable to meet demand. They purchased a disused 15,000 square feet

warehouse with an included 2,000 square feet of accommodation for £240.000.

Over the next fifteen years, the business continued to expand. Despite little

marketing, the demand still increase. The product had high quality, and wordof-mouth reputation seemed to be enough to maintain sales.

By 2010, the business is in trouble. Costs are rising, the bank manager has

expressed concern about the overdraft. Meanwhile, price have been reduced to

maintain sales. The product caused mistake and had the Customer complaints.

Production

The products are mostly handmade and made in the open former warehouse.

Dai himself still makes all the frames, using the original jigs constructed in his

garage all those years ago. Steel tube stock is cut to size using an old automated

tub cutting saw and an ancient but effective tube bending machine. He can make

eight fames a day, but his other duties as factory manager and business director,

it is too hard to keep up with the order. He want invest the merits of robotic

flash butt welding machines with his colleagues, but they are not accepted

because of the risk.

Maldwyn Jones, also a former steel worker, paints frames as and when required.

He was very active in the work and often helps other parts although not a

member board of directors. Due to issues of quality paint, some frames were

removed, some devices no longer use the well again and affect the environment.

The problem arises here that need a large amount of capital to invest in

machinery.

Assembly process is relatively complex, take 2 to 3 hours for a complete

assembly drawing frame assembly. Janice Jones and Ffred Gregory were

responsible for this process. However, Fred is too young and does not have

experience for this, and always make the process which was slowed.

Job quality inspection and packaging proved to be unprofessional and

inefficient.

Wheels, mudguards, chain guards, stays and other necessary hardware are

manufactured in parallel with the frames. Idris Pugh is a perfectionist, whose

wheels are always absolutely true, and never the cause for complaint. But he

have the health problems and the company sometimes must outsource with

higher cost.

Emlyn Morgan, he was a man skilled in plant maintenance. Also can add a

certain number of jobs as steel pressing, painting or assembly when required.

One problem in the production of factory inventory items too large while the

material is still to enter.

The only other employees are two part-time workers; Ianto Prichard works

weekday mornings, as “odd-job” man and cleaner in the factory, and Gladys

Wells cleans the office twice a week for an hour or so.

Administration

Friedra Scholock and Gwyneth Morgan were the people have the ability in

financing. They manage the wages and salaries by a software package provided

by the bank. Morgan is very concern about manage the inventory.

Management and Corporate Structure

Cyclermate Ltd has three shareholders, Lewis Llewellyn, Dai Armstrong and

Linda Llewellyn. Shares are held equally between the three shareholders. But

now, Lewis and Linda are divorced. She want return of her money.

A former colleague of Dai’s, Geraint Williams, agreed to invested a long team

loan for company with competitive rate of 10% per annum.

Lewis and Dai have the equal salaries.

Financial Matters

Following the financial statements, total costs is more and more increase, while

profit decreased and have no dividend for shareholders. The bank loans fall into

the predicament.

Clyclermate Ltd

Present:

Dai Armstrong (chair)

Gwyneth Morgan (secretary)

Lewis Llewellyn

Frieda Schlock

Maldwyn Jones

Betty Barry (representing Cyclermate’s’ accountants – Davis, Davies and

Davis)

There have been many comments raised about the company is facing, there are

solutions, ideas and thoughts of each member is given but is not yet a unified

optimal solution for the company at now

I.

Introduction

The report focus on the existing situation and cost and efficiency changes that

could quickly be made in the coming months. Therefore, I deal with the

financial problems and various other problems confronted by Cyclermate. The

chief function of this report is to examine how the company could get out of the

crisis and get back to the lost market share.

I will use SWOT analysis to see the internal problems of company. From this, I

forecast the situation of company in the near future. Besides, I also give some

recommendation to find the best way for the survive of company.

II.

SWOT analysis

Strength

Skilled workers

Possession of buildings and

land

Handmade product

Staff is to express an opinion

and join discussion

Direct Sales Channel

Simple corporate structure

Opportunity

New staff are trained at low

cost

Well known on the market

products handmade bicycle

Attracting

customers

in

making product category

modern bikes

Start using advertising in

business

Weakness

Employees increasingly older

New employees also poor

workmanship

Understaffed

Machines downgraded

Lack of funding

Do not focus on advertising

Threat

Low productivity and not keep

up orders

The company's reputation is

increasingly going down

Intense competition with cheap

foreign products of good quality

The staff started with the idea to

leave the company

Strength

S1: Skilled workers:

Lewis Llwellyn and Dai Amstrong were the founders of the

company and they have more than 20 years which worked in steel

company in south Wales. Lewis had worked his way up from

apprentice to be chief mill engineer, and Dai had progressed from

“office boy” to a senior marketing post. So that they can manage

employees to produce high quality products. They also have the

capacity for people to listen to.

Maldwyn Jones, also a former steel worker, paints frames and have

ability in management and production.

Idris Pugh is a perfectionist, whose wheels are always absolutely

true, and never the cause for complaint.

Emlyn Morgan, also has the skills to undertake all of the factory

maintenance, and he can turn his hand to steel pressing, painting o

assembly when required.

Frieda Schlock and Gwyneth Morgan have skill on accounting and

deal with others internal and external problems.

S2: Possession of buildings and land

Unlike Cyclermate most of the companies don't possess either

building or land and hence have to pay the heavy rents which adds

to the cost but cyclermate can make any changes in the buildings

and could capitalize in whichever way they wish to as they own it,

which reduces the overall cost.

S3: Handmade product

Almost the product of Cyclermate Company were made by hand

with the little help of rudimentary machines. This will make their

product are made carefully, drawing and painting nature of

creativity.

S4: Staff is to express an opinion and join discussion

Employees can play an important role in the overall development.

The staff is available to companies that are creating new ideas

worth exploring, they were learned the job from other parts and are

considered comments by superiors.

S5: Direct Sales Channel

Cyclermate has direct channels of sales with the direct sales and

direct shops, hence intermediaries cost is largely eliminated.

Reducing the cost of manufacturing could unquestionably help

Cyclermate achieve a huge share of the market. As direct channels

are in direct contact with the providers, thus, it could help in

increasing in quantity or value of the sales and it provides a good

opportunity to the providers to empathize the clients and could

make required changes are per the requirement of the customers.

(Jan, 2002)

S6: Simple corporate structure

The number of employees and manager are small, they are easy to

manage and arrange the work which conform with ability of each.

Weakness

W1: Employees increasingly older

Besides age comes with experience, the issues of health and catch

new technology becomes horizontal resolution. Idris Pugh is 70

years old and not in the best of health.

W2: New employees also poor workmanship

Fred, who is 18 years old, is fairly new to the process, and training

him has further slowed production recently

W3: Understaffed

The company only has about more than 6 employees and managers.

Sometimes, Lewis and Dai must do the work when work overload.

The help of other parts will occur error because they do not have

expertise.

W4: Machines downgraded

Steel tube stock is cut to size using an old but automated tube

cutting saw and an ancient but effective tube bending machine. The

elderly compressor and extraction equipment will not adequately

protect against the dangers of highly toxic paint materials.

W5: Lack of funding

The Company management are deeply concerned both about the

loss of profitability, and, more urgently, the rapidly rising

overdraft. The bank manager has indicated that increased overdraft

facilities are not likely to be made available unless there is

convincing evidence of improved trading conditions in the coming

year. Unfortunately, the budget suggests that a loss is more likely.

Debts may difficulty to take on, individual issues of a shareholder

to be a big trouble while need a large amount of capital to invest in

machinery and maintain business

W6: Do not focus on advertising

The company did not advertise on flyers, newspapers or magazines

which only uses direct advertising and marketing orally with

bicycle retailer. Therefore, customer brand known only in a certain

range, and transient nature.

Opportunity

O1: New staff are trained at low cost

The company has available a staff of skilled and experienced.

Therefore, when the newly recruited staff will lose a small amount

for training costs. The treatment is also less expensive.

O2: Well known on the market products handmade bicycle

Since its incorporation in 1988, the company has built brand

bicycle was processed by hand more than 20 years. It is also the

strengths and opportunities for business development in the future.

Since then, we try to limit the technical error in production to keep

customers, while creating a new product line on the reputation

already.

O3: Attracting customers in making product category modern

bikes

Currently, the traditional bicycle market went down, the company

should catch up with the trend to produce modern bikes. This

opportunity should be integration trend of the world market.

O4: Start using advertising in business

Since its inception, the company does not focus on ad. Now is just

the beginning for this. We advertise the existing products as well as

upcoming products and to use reasonable funds for this phase.

Threat

T1: Low productivity and not keep up orders

Because of the company's products are mainly by hand, too little

staff numbers, health problems and ability to work so sometimes

companies do not keep order. Outsourcing also apply when this

happens but far more costly and with fewer orders in the future,

then it is no longer effective.

T2: The company's reputation is increasingly going down

The complaint about the causes of accidents and affect human

health has made the reputation of Cyclermate significantly

diminished. The product testing also become tougher but by

machines increasingly degraded and the products removed also

increasing.

T3: Intense competition with cheap foreign products of good

quality

On the bicycle market in Europe is no longer the exclusive nature,

economic integration has brought competition to the products

bicycle Asian countries, especially China and Taiwan where the

labor force upholstered, low-cost but quality assurance.

T4: The staff started with the idea to leave the company

The poor development of the company is the main reason causing

the problem of employees want to leave. Also, some people think

that they have not been properly evaluated its capacity caused no

consensus on the job.

III. Company issues and solution

1. Production and operation

1.1. Technology

Problem

The machines used in the factory are mostly those that have had a

long period of use as the use of jigs originally built in the garage all

those years ago.

They do not upgrade a robotic flash butt welding machine because

they could not justify the investment risk.

Until recently a “traditional” cellulose spray technology was used

but it is showing signs of deterioration and substandard.

Consequence

Not guarantee about quality (so many complaints recently have

been about paint quality)

Not guarantee about quantity (have to work overtime to ensure that

orders are met on time; commissioned a cycle shop in Cardiff to

build the wheels)

Reduced sales

Solution

The imperative now is technological innovation to product quality

is guaranteed, the order is now not so much as before so to retain

the existing customers.

1.2. Method:

Problem

All production processes are using the classical method ( use

manpower )

The products in Cyclemate mainly processed by hand, the division

of labor is not fair that some people work too much while others do

not have work to do.

Consequence

Waste of time: Workers often have to work overtime, each step it

takes 2-3 hours for a product

Low productivity: For instance 8 frames of a cycle are produced

each day with labor but if new technology is implemented then 25

or more frames would be produced each day.

Errors: The delay in making the job orders become quick and

error rates is higher

Solution:

Need to replace human labor with machinery, people just set up,

install and test the process, the rest will come from machinery to

undertake.

1.3. Human resouces

Problem:

The number of workers too little to cause a shortage of personnel in

the stages. For example, the product testing conducted by a novice

with no experience work while it is an important step to assess a

product. When Idris sick, no one replaced in making tires. No

specific personnel in the packaged product

Consequence:

Many complaints in car quality

We spend a larger amount than the original to outsource by

Cardiff.

Solution:

Training more skilled workers generation

Always ready with a replacement when the problem of unwanted

happens

Delay orders

1.4. Inventory materials

Problem:

There are too much raw materials

Consequence:

Materials will be depreciated over time while the company does

not have the capital to the business. It's too big waste.

Solution:

The company may sell some of this material to another company or

receive extra work to earn additional income.

2. Human relation

The staff does not meet the needs of the job

Idris Pugh is over 70 years old, he always cause the health

problems, Dai can meet the demand skills necessary but not always

he is free. Therefore, the firm has commissioned a cycle shop in

Cardiff to build the wheels for it; these are of reasonable quality

and are always delivered quickly, although the direct cost is

somewhat higher than the materials and components used by Idris.

Fred, who is 18 years old, he has not have experience in the job so

often causes slow production. In addition, he also is responsible for

product testing after being completed, it is not efficient and it is

evidenced by complaints from customers about the quality of

products.

Individuals do not have responsibility for the development of the

company

Besides the enthusiasm and his dedication to the company as Dai

Armstrong, the company remains the only worry for the personal

benefit of himself:

Lewis Llewellyn, he is one in two the head of the company, Mr

Llewellyn is less optimistic than Mr Armstrong about the

Company’s future. He feels that the time has come for the

Company to recognise the inevitable and either simply close down,

or try to sell to one of the other UK firms that manufacture or

assemble cycles. Mr Llewellyn also noted that he finds his work

increasingly tiring and stressful, and that he would be happy to

retire.

Linda Llewellyn, she was Lewis’wife, but now they are divorced.

She does not take part in the running of business, she only invested

a legacy from a family member, was given shares in return. But

now she want return of her money while the company is difficult.

Maldwyn Jones, he is thinking that he will leave the company to a

Chinese company or Taiwan.

Staff not find out the problem but only give theoretically solved.

Therefore, when not enforced the idea they think their

qualifications were not assessed properly. This is expressed

through the thinking of Morgan.

No specialization at work

The parts that have not been assigned correctly, the phenomenon

still understaffed and do not correct professional work. Therefore

need to retrain all workers are properly written and its expertise to

the work of high quality.

Lack of motivation at work

While the company is having problems, it feels vague and lack of

motivation is understandable. But companies can overcome it, the

tight discipline, create rules reward and punish is a logical

necessity. Employees need to understand their capabilities, and also

should not be underestimated it.

3. Marketing

Importance of Marketing has not been appreciated. The company only

uses word of mouth and direct sales to advertising companies. It will not

work in this tough market. The company should study and provide timely

forms of advertising in this time and develop it as a key tool to increase

sales.

4. Financial projections

Problem

As can be seen that any company need a large amount of cash to perform its

operations. But Cyclermate has only £675 in the bank and running expenses of

more than £110k each month. The main problem that company is in this

situation is because of the uncontrolled cost and mismanaged budget. The costs

are increasing yearly with the sales and selling price of the products going

down. The company is going through the financial crisis.

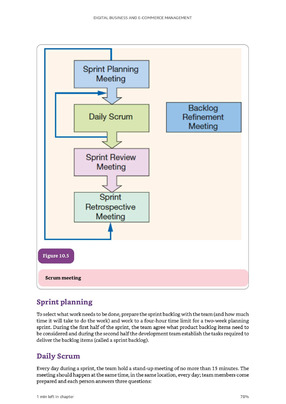

Income statement over last five year

1,800,000

1,600,000

1,400,000

1,200,000

£

1,000,000

800,000

600,000

400,000

200,000

0

30/09/2006

30/09/2007

30/09/2008

30/09/2009

30/0/2010

Years

Tota l revenue

Tota l costs

Profit reta i ned

Companies are to pay for Linda Llewellyn while the company has no

dividend for 2010. Therefore, Lewis would have to mortgage their

shares to pay for his wife.

Wages of workers while increasing profits for the year went down.

Acid ratio for the company is 0.76:1, which shows the company is

unable to meet short terms obligations, i.e. the company won't be able

to meet any financial problem occurring in future.

Asset turnover ratio is 2.06:1. This indicates that the profit margins for

the company are very low that's why the ratio is so high. We can also

conclude from this that the company's pricing strategy is not effective

leading to lower profits.

Return on capital employed - The Company is just getting a return 0.11

on the capital employed. Far too less than required.

Debtor days - 115 days. So it will take approx 115 days to receive back

money from debtors

Creditor days - 24 days. So the company has to pay back it its debtors

in 24 days and it is just left with 675£ of cash.

Solution

Dai is looking for investors for the company: friend from Liverpool

want to retire in Wales but also looking forward to a job here.

Mortgaging the freehold land - The Company has a free hold land

£160,000. It can mortgage the same to the bank for an agreed period of

time and raise out funds. Even after the revaluation and charges from

the bank they still may avail estimated £150,000 of cash. This way of

bank loans will be much, but parallel to it, the company must pay more

interest. Besides, we can lease the land and take money periodically.

Debtors - The Company has debtors of £200,571. The company can

have word with the debtors and try and explain them the current

scenario of the company and convince them if they can release some of

the payments in advance. Even if they don't agree for releasing the

payments, the company can exchange bills with the bank in return of

some cash. Bank may check the credit history of the debtors of

cyclermate and will deduct its charges; they can still raise estimated

£185,000 from these bills.

Creditors - The Company is liable to pay £87,500 to the creditors and

if they don't so a legal action may be taken on them which are not good

for company's reputation. They may talk to the creditors and ask for an

extension in time for payments as they are going through financial

crisis and don't have money right now to pay back.

Wages - Wages are increasing year after year though the sales are

going down. So in order to enforce cost cuttings the wages should also

be decreased. Though it has just occurred once in history of United

Kingdom that the workers agreed for a wage cut, but still the managers

can try and talk to the labourers for decrease in the wage cut and

reduce the working hours so that there is no over production as we see

now. Managers may promise than increments once the company is

stabilised again. This is the first application with Dai Armstrong that he

take a salary to work in the future and when the company makes a

profit he would receive salary plus percent dividend.

Sale of materials and inventory. Signing the contract performed part

machining for a large company to get more income

IV.

Recommendation

1. Short- term

Conducting discussions with creditors and debtors to claim the debt

and extend repayment date.

Mortgages unused land to the bank to obtain investment capital

Signing a contract with a major company to become a part of the

processing (how this is carried out in a short time to earn extra

income is just to learn new technologies)

Conduct a simple advertising leaflets (matching state budget less)

Open vocational training courses to recruit workers without any extra

cost (extra part of training funds)

Reducing short-term wage workers and salary percentage increase in

future

Set the rules, assign work according to expertise, rewards and

punishments prescribed

Increased product quality, safety checks to avoid complaints and

belittling.

Research to develop new products

2. Long-term

Renting land, after the company stability and development, the

construction of a large-scale factory

Proceed to the modern bicycle, remain traditional bicycles but with a

smaller number

Develop marketing through leaflets, on magazine ads, TV

Continued development of vocational training

Buy more new machines to replace the machine was used for too

long, to learn the skills to make products such modern bicycle wheel

drive, mountain bike, electric bike.

V.

Conclusion

This report are given for reference and together discuss. Although

there are some minor flaws, but they were understanding and

analyzing very carefully through the issues that companies face.

VI.

References

- Problems Confronted By Cyclermate Commerce Essay available at

http://www.ukessays.com/essays/commerce/problems-confronted-bycyclermate-commerce-essay.php#ixzz3sPjloEDV assessed on 30-11-2015

- Financial And Other Problems Faced By Cyclermate Finance Essay available

at

http://www.ukessays.com/essays/finance/financial-and-other-problemsfaced-by-cyclermate-finance-essay.php#ixzz3sy4isXDQ assessed on 30-112015

- Xem thêm -